The process of creating vinyl stickers with letters is not particularly difficult. Success will depend on the quality of the film. In our work we use proven materials from well-known manufacturers. Therefore, we guarantee that our products will meet the expectations of customers in all characteristics.

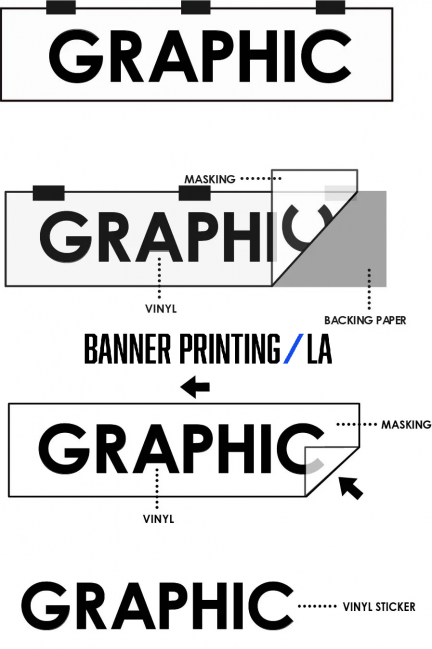

Eay steps to apply vinyl lettering

- Step 1 – Position And Secure With Tape;

- Step 2 – Remove The Liner;

- Step 3 – Wet Surface & Vinyl Adhesive;

- Step 4 – Apply the Lettering Pushing The Water Out;

- Step 5 – Wet The Transfer Tape;

- Step 6 – Remove The Transfer Tape.

Features of vinyl lettering

If the sticker is made of high-quality materials, then it is characterized by resistance to abrasion and accidental tears. The inscriptions on it are bright and contrasting thanks to the use of high-quality paints. Stickers with spectacular slogans will help mask the surface on which there are signs of wear. As a result, the product will look in a new way.

What layers the sticker consists of:

- The front layer is made of plasticizers and PVC. It is represented by a high-quality film. If the conditions of the manufacturing process are not met, the sticker will not last long, because its base will shrink.

- The adhesive layer is applied to the previously clean surface. It consists of a universal water-based adhesive, or a mixture of foam with a solvent. As practice shows, stickers with adhesive tape from an organic solvent used in the production have a longer operational life. However, their production will cost more.

- The third layer is represented by a sticker backing, which is made of paper. It is mandatory to treat the base with silicone on one side. Sticker backing must be completely removed before applying the letters to the prepared surface.

Vinyl film is used for the production of stickers on any type of surfaces, the thickness of which ranges from 0.07-0.1 mm. Thanks to the thin film layer, it is possible to achieve maximum fit of the inscriptions to the surface.

We use a special film made of photoluminescent material for making luminous stickers with inscriptions. It contains a phosphor, which provides uniform light scattering in the dark. Such inscriptions on the glass will attract attention from afar.

Type of printing

Digital printing is suitable for limited editions of stickers whose size does not exceed A3. The inscriptions will be carefully detailed, but the sticker will cost more. This is explained not by the complexity of the process, but by expensive equipment. Large format printing is a popular way of applying images to the base. It can be either white or colored.

When using sublimation printing, maximum efficiency can be achieved. The ink penetrates as deep as possible into the base, due to which the paint is well fixed. Such stickers are characterized by maximum durability.

Production process

The production of stickers with lettering takes place with the help of high-precision modern equipment. An automatic cutting machine or plotter is used in process. With the help of it, letters are cut out according to the specified contours. In general, the procedure is not complicated. However, it will require increased accuracy. The letters differ from each other in shapes. Some of them are open, others are closed. A professional plotter will help bring to life any ideas of a designer who takes into account the wishes of the customer.

Before the order is accepted, you will be asked to measure the surface and provide accurate data. Our specialists will be able to assist in carrying out measurements. They will also take on the responsibilities to apply the lettering and surface preparation.

We provide customers with information support at all stages of production and guarantee the high quality of our products. We will try our best to get you to contact us again.

0 comments

There are no comments yet. Be the first one to post a comment on this article!

Leave a comment